Hardware resources for the Infinite WiFi Portal.

| 3mf | ||

| image | ||

| pcb | ||

| plas | ||

| step | ||

| README.md | ||

Infinite WiFi Portal

This repository contains the resources used for creating the Infinite WiFi Portal hardware.

Todo: add PCB resources, laser cutting resources, weights and times

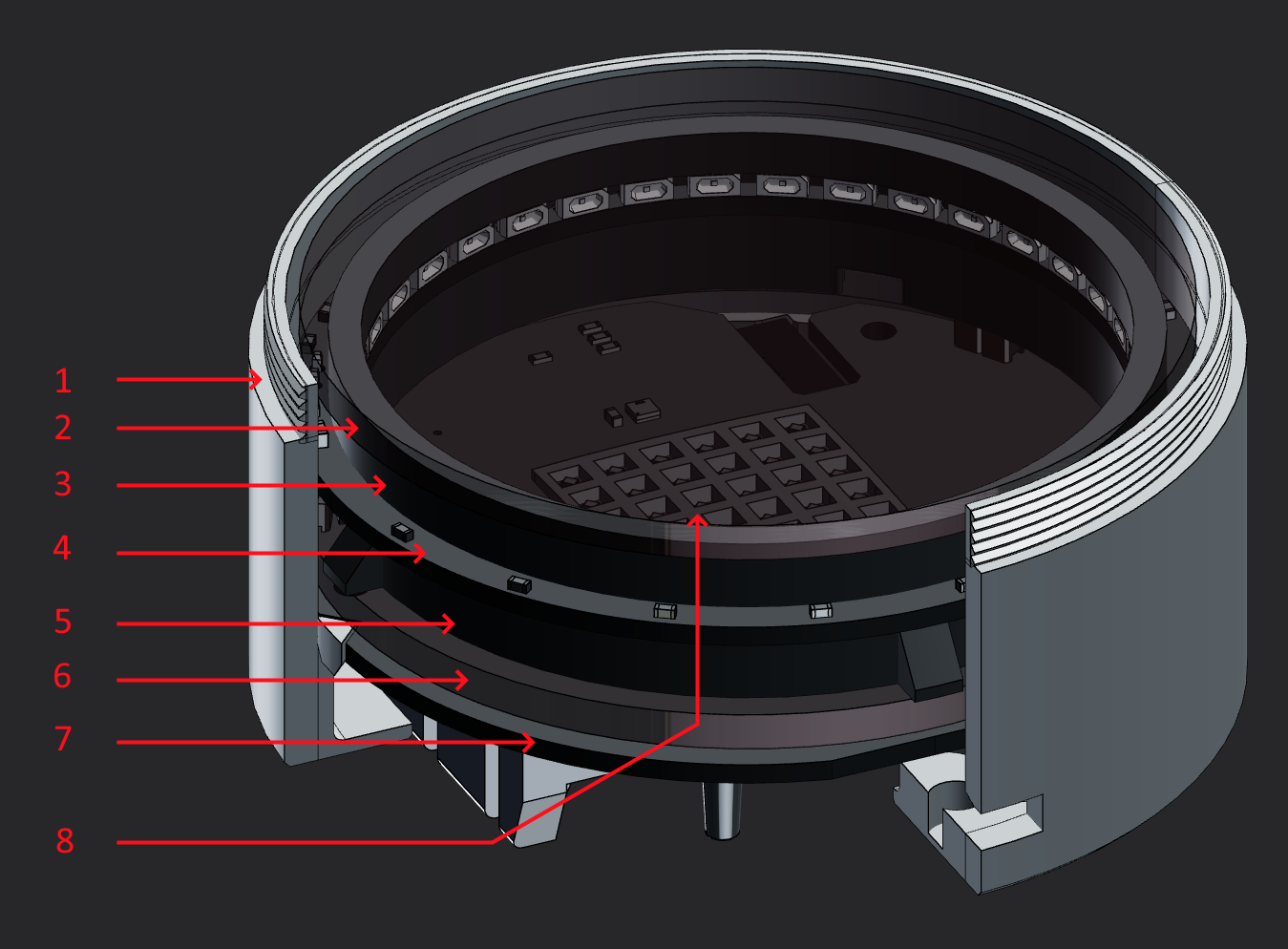

Assembly Breakdown

1. Outer Case

- Fabrication Method: FFF

- Material: PETG

- Color: Various

- Weight: ~24-29g

- Estimated print time: ~2-3 hours/ea

2. Upper Acrylic

- Fabrication Method: CO2 laser

- Material: 3mm acrylic

- Color: Iridescent coated

- Weight: tbd

- Estimated cut time: 20 seconds/ea

3. Upper Isolator

- Fabrication Method: FFF

- Material: PETG

- Color: Matte Black

- Weight: tbd

- Estimated print time: tbd

4. LED Ring PCB

- Assembled by PCB fab

- 2 layer board

- Single layer load

5. Lower Isolator

- Fabrication Method: FFF

- Material: PETG

- Color: Matte Black

- Weight: tbd

- Estimated print time: tbd

6. Lower Acrylic

- Fabrication Method: CO2 laser

- Material: 3mm acrylic

- Color: Iridescent coated

- Weight: tbd

- Estimated cut time: 50 seconds

7. Main PCB

- Assembled by PCB fab

- 2 layer board

- Two layer load (top and bottom)

8. LED Array Grid / Acrylic Curver

- Fabrication Method: FFF

- Material: ABS

- Color: Black

- Weight: tbd

- Estimated print time: ~5 minutes/ea

9. Lid (not pictured)

- Fabrication Method: FFF

- Material: PETG

- Color: Various

- Weight: tbd

- Estimated print time: ~15 minutes/ea

10. Hanger (not pictured)

- Fabrication Method: CO2 laser

- Material: 3mm acrylic

- Color: Clear

- Weight: tbd

- Estimated cut time: 20 seconds

Additional Hardware

- Lower Acrylic attached to Main PCB using 3x M2.5x5 Phillips screws, 3x M2.5 nuts, 3x M2.5x1 nylon spacer washers

- Hanger attached to Outer Case with 2x M3x5 or M3x6 flat head machine screws, screwed into M3x3x5 brass heat set inserts

Fabrication equipment used

FFF 3D Printers:

- 3x Neptune 4 / 4 Pro (production)

- Bambu Lab X1 Carbon (prototyping)

- Bambu Lab A1 mini (prototyping)

Laser Cutting:

- true's China 5070 80W

PCB:

- Fabbed and assembled by a PCB house